D-Sub Connectors

The D-subminiature connector, more commonly known as a D-sub connector takes its name from the D shape within which the pins sit. These types of connectors are primarily used for communication and network ports within computing. Even though the D-sub connector is of an older style it is still widely used in many industries due to its rugged nature. D-subs are also available in a wide range of varieties from the standard and high-density style through to filtered, dual-port and combi style, with waterproof IP67 / IP68 options available. The combi style allows a combination of signal, high-current, high-voltage, coaxial or even pneumatic contacts to be placed within a single housing.

View Frequently Asked Questions about D-Sub ConnectorsDeltron AG IP67 / IP68 D-Sub connectors

The extensive range of Waterproof D-subs from Deltron AG are high quality and robust connectors designed for the most demanding applications and manufactured in their factory in Switzerland....

View ProductGT Contact IP67 / IP68 D-Sub Connectors

The D-Sub series of waterproof input/output connectors from GT contact are highly ruggedised connectors sealed to IP67. The D-Sub series panel connectors are rear potted giving protection to products even if the connector is unmated or sealing cap not connected....

View ProductFiltered D-Sub Connectors

The filtered D-Sub connectors from Deltron AG are produced to an exceptional quality at their factory in Switzerland. The FP and PI filter connectors have been specially developed for high-end industrial applications and offer excellent protection against EMI (electro-magnetic interference) and RFI (radio frequency interference)....

View ProductPress-fit D-Sub Connectors

The extensive range of Press-Fit D-subs from Deltron AG are high quality and robust connectors designed for the most demanding applications and manufactured in their factory in Switzerland....

View ProductStandard D-Sub Connectors

The extensive range of standard D-subs from Deltron AG are high quality and robust connectors designed for the most demanding applications and manufactured in their factory in Switzerland....

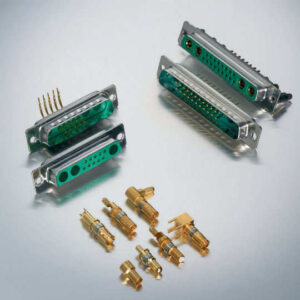

View ProductHigh-Density D-Sub Connectors

The High-Density D-Sub connectors from Deltron AG are designed for applications which require the best possible contact density. These connectors are all produced to Deltron AG’s high specifications and are ideal for most modern industrial and commercial applications....

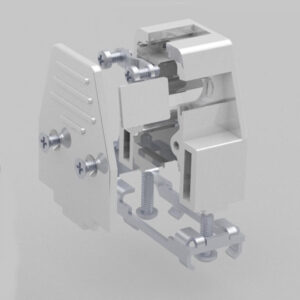

View ProductD-Sub Hoods

The D-Sub Hoods from Deltron AG are designed to perfectly match their range of high-quality D-Sub connectors. Available in 9, 15, 25, 37 or 50 pin versions with a choice of UNC4-40, M2.5, M3 threads or with a sliding lock....

View ProductDual-Port D-Sub Connectors

The Dual-Port D-Sub connectors from Deltron AG are an ideal solution when multiples D-Sub connectors are required but space is at a premium. Through the stacking of two 90° D-Sub connectors, one on top of the other, Deltron are able to create a single dual-port connector with a very condensed footprint....

View ProductCombi D-Sub Connectors

The Combi D-Sub connectors from Deltron AG are a hybrid connector featuring different connector styles within a D-Sub housing. This allows designers the ability to have a mix of different contacts within a single D-Sub whether these be signal, high current, high voltage, coaxial or pneumatic....

View ProductFrequently Asked Questions about D-Sub Connectors

D-Sub is the shortened and more widely used name for a D-subminiature connector. These are a style of connector which have a D shaped housing in which sits different numbers of electrical contacts. However, with recent advancements some D-sub combination connectors are able to include non-electrical contacts e.g. hydraulic connections.

D-sub connectors are primarily used for transferring data and signals such as images or sensor signals. As such they are used predominantly for networking and communication within a computer system or transferring image signals to monitors.

A VGA connector is a type of D-sub connector that includes 15 pins in a specific layout. A VGA connector is a particular type of connector whereas D-Sub refers to an entire family of connectors.

Our D-sub connectors are wired in three different ways; PCB mounted, soldered or crimped. The PCB mounted style are pre-made D-sub housings that are designed to fit directly into a printed circuit board, after which the terminals are hand or flow soldered. Solder type D-subs are also pre-assembled. They have solder bucket termination which allows the wires to be soldered directly to the rear of the connector. Crimp style D-subs require the use of a crimping tool, by stripping the sheath off of the connecting wire and placing a crimp over the exposed wire you can then use a crimping tool to attach the crimp to the wire. The crimps are then inserted into the correct position on the D-sub housing. A D-sub hood is used to enclose the rear of cable-mounted connectors. Some waterproof hoods have a press-fit design, and when using these it is important to ensure that the hood is fed onto the cable before soldering or crimping the wires.